July 3, 2018

By: Michael Feldman

ANSYS, Cray, and a university researcher have conducted the first aerodynamic simulations of a full peloton of road cyclists, yielding some unexpected results.

If you’re not in the cycling world, a peloton is the term for the main group of riders in a road bicycle race. A peloton is used by teams to minimize air resistance for riders in the interior of the formation by taking advantage of the shelter provided by other riders on the exterior. The idea is to optimize the amount of energy expended during the race in order to maximize team performance, especially for the team’s elite riders. As such, pelotons are the basis for much of the strategy around these competitions.

If you’re not in the cycling world, a peloton is the term for the main group of riders in a road bicycle race. A peloton is used by teams to minimize air resistance for riders in the interior of the formation by taking advantage of the shelter provided by other riders on the exterior. The idea is to optimize the amount of energy expended during the race in order to maximize team performance, especially for the team’s elite riders. As such, pelotons are the basis for much of the strategy around these competitions.

It was thought that riders in the middle of the peloton would save as much as 40 to 50 percent of their energy compared to a lone cyclist as a result of reduced air resistance. That was based on fairly simple mathematical models without the benefit of digital modeling. However, anecdotal information from actual racers suggested the drag reduction was much greater.

As it turns out, they were right.

Simulations conducted by Professor Bert Blocken of Eindhoven University of Technology and KU Leuven on an XC-class Cray supercomputer running ANSYS Fluent CFD software found that air resistance is only 5 to 7 percent that of a solo cyclist – an order of magnitude smaller than what simple calculations had indicated. That makes it about four times easier to pedal in the middle of the peloton than if you are cycling by yourself.

The aerodynamic simulations modeled a full peloton of 121 cyclists, comprising three billion cells. To get accurate air resistance data, the calculations were performed as close as 0.020 millimeters from the surface of the rider and the bicycle. The computations used a total of 108 supercomputing hours across 13,824 processes. According to ANSYS and Cray, this is the largest fluid dynamics simulation using commercial software, as well as the largest aerodynamics sports simulation ever performed.

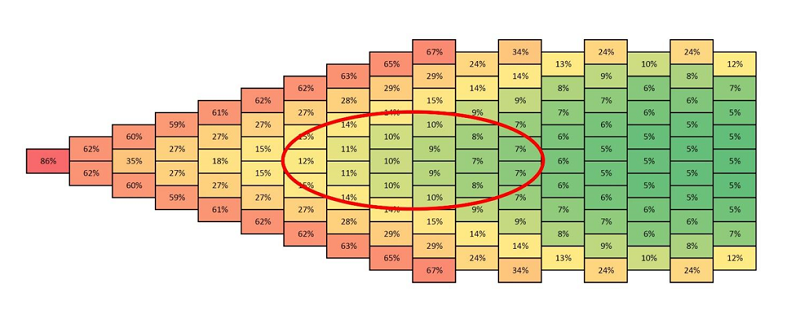

The simulations indicated that the lowest drag is experienced in rows 12 to 14, but they also found that everyone, even the lead cyclist, derived some benefit from being part of the peloton. The various reductions in air resistance (compared to a lone rider) are illustrated below.

According to Blocken, the results were so surprising they conducted wind tunnel testing to validate the results, which they did. He thinks the newly discovered knowledge will have practical application for racers in competition. “These results teach them how important it is to stay well sheltered in the peloton as long as possible: you save a lot of energy and remain fresh until the final rush of the race,” explains Blocken.

Although this is not exactly a “grand challenge” application, it does illustrate the how useful these simulations can be for problems that have remained largely unexplored. “In a time when simulation is crucial to accelerate and amplify innovation for high tech industries, the peloton project and its surprising results illustrate that this simulation technology is truly pervasive and can make a huge difference in a popular sport such as cycling,” concludes Thierry Marchal, Global Industry Director for Sports and Healthcare at ANSYS.

For a deeper dive on the technology, along with an accompanying video and a pointer to the case study, check out the Cray write-up here.